ISO 9001: Elevating Excellence in Quality Management

Quality Management ISO 9001 is an internationally recognized standard that plays a vital role in elevating excellence in quality management. In today’s highly competitive business

AKAP Accreditation Organization

The PDCA Cycle is one of the most widely recognized tools for quality management and continuous improvement in organizations. Originally developed by Walter Shewhart and popularized by W. Edwards Deming, the method is also referred to as the Deming Cycle or Shewhart Cycle. Today, it forms the backbone of Kaizen and other continuous improvement approaches such as Lean, Six Sigma, and Total Quality Management.

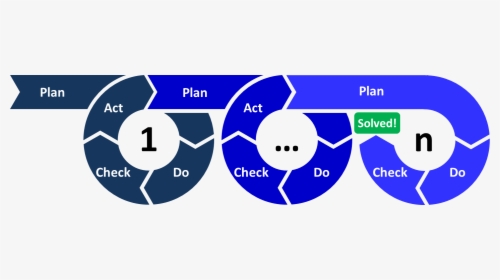

At its core, PDCA is a four-step iterative method that drives organizations to continually assess, refine, and improve their processes. The steps—Plan, Do, Check, Act—work in a loop, just like a circle with no end, ensuring ongoing progress toward higher efficiency, reduced waste, and improved customer satisfaction.

The PDCA Cycle (Plan–Do–Check–Act) is an iterative management method used for the control and continuous improvement of processes and products. Although W. Edwards Deming introduced it to Japan in the 1950s, credit for its original development goes to Walter Shewhart. Over time, Deming preferred the term PDSA (Plan–Do–Study–Act), believing that “study” encouraged deeper analysis than “check.” Despite this, PDCA remains the most widely used term today.

Many modern quality frameworks—such as ISO 9001, Lean, and Six Sigma—draw on PDCA as their foundation. The method is simple but powerful, making it applicable to small teams as well as large corporations aiming for organizational excellence.

The planning stage is about fully understanding the current state of a process and identifying opportunities for improvement. This involves analyzing inputs, outputs, customers, and constraints. Tools like SIPOC (Suppliers, Inputs, Process, Outputs, Customers) are often used to map the process clearly.

Specific steps in the Plan stage include:

Thorough planning ensures the team starts improvement efforts with a clear vision, reducing the risk of wasted time and resources later in the cycle.

Once a solution is defined, the next step is to test it on a small scale. This is the experimental stage, where organizations evaluate the potential effectiveness of proposed solutions before committing to full-scale implementation.

Specific steps in the Do stage include:

The Do stage helps organizations reduce risk. By running a pilot project, leaders can gather valuable data and make informed decisions before scaling changes across the entire organization.

The Check stage assesses whether the changes are producing the expected results. This stage emphasizes data-driven decision-making and encourages reflection on what has been learned during the trial.

Specific steps in the Check stage include:

If the results show improvement, the organization can move forward. If not, adjustments are made, and the cycle may return to the Plan stage for further analysis.

The Act stage involves standardizing and institutionalizing successful improvements. It ensures that the refined processes become the new “best practice” for the organization.

Specific steps in the Act stage include:

Once the changes are implemented, the cycle doesn’t stop. The process is repeated continuously, which is why PDCA is described as a never-ending loop of improvement.

The PDCA cycle is more than just a quality tool—it’s a mindset. Organizations that adopt PDCA cultivate a culture of continuous improvement. Instead of reacting to problems, they proactively analyze and refine their systems. This leads to:

Industries ranging from manufacturing to healthcare, IT, and education rely on PDCA to systematically drive excellence.

The PDCA cycle connects closely with methodologies like Lean, Six Sigma, and Total Quality Management (TQM). All these approaches emphasize employee involvement, data analysis, and process standardization. PDCA acts as the underlying framework that ensures systematic testing and implementation of improvements.

The PDCA cycle (Plan-Do-Check-Act) is a proven, repeatable model for continuous improvement. By systematically applying its four steps, organizations can reduce errors, enhance customer satisfaction, and build a culture of learning. Just as a circle has no end, the PDCA cycle must be repeated continuously, ensuring that improvement becomes an ongoing process rather than a one-time project.

The PDCA Cycle is closely related to several international management standards that emphasize

continuous improvement and quality management. Some of the most important standards include:

By aligning PDCA with these standards, organizations can build a strong foundation for sustainable

growth, compliance, and continuous improvement.

Quality Management ISO 9001 is an internationally recognized standard that plays a vital role in elevating excellence in quality management. In today’s highly competitive business

What does SWOT stand for? SWOT stands for Strengths, Weaknesses, Opportunities, and Threats, and so a SWOT Analysis is a technique for assessing these four aspects of your